Highlights

• Ensure component data integrity by validating properties against a corporate database. For example, a simple schematic modification such as changing the value of a resistor without changing the corresponding footprint and/or part number can result in a mismatch between the schematic, PCB layout, and BOM. Such a mismatch design can easily result in an expensive, unnecessary board re-spin.

• Optimize part selection to help meet project milestones and goals. For example, inadvertently identifying and utilizing an obsolete component or one with a long lead-time or incorrect supplier can cause an unplanned, costly delay. All too often, these problems aren’t discovered until the product is on the verge of being manufactured.

• Promote the use of company preferred components to help meet corporate initiatives and goals. For example, without access to cost or corporate initiative information during the design stage, it’s easy to introduce higherpriced parts and miss the opportunity to use equivalent lower-cost substitutes from the same or alternate supplier.

• Reuse known good part data to help eliminate duplicate effort and improve efficiency. For example, redundant or duplicate parts are often introduced into engineering libraries and corporate inventory when functionally equivalent parts are already available and in stock.

Features

Database query and component placement

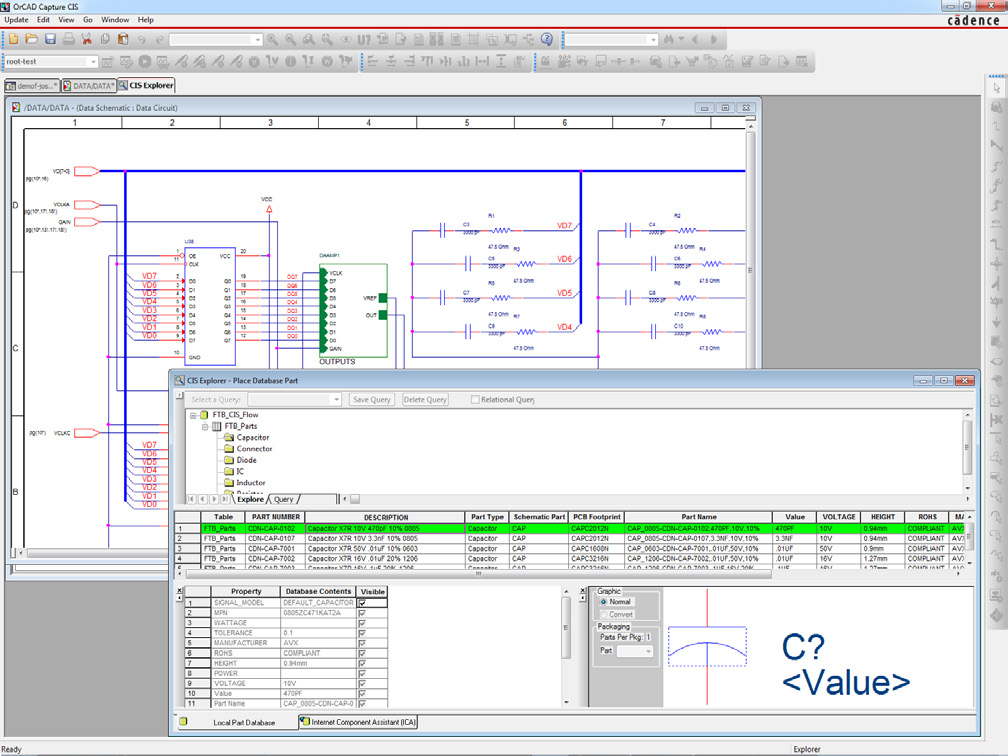

With OrCAD CIS, you can explore, query, and filter database components according to specific criteria that may becritical to your project goals (such as value, cost, availability, etc.) to identify the exact component needed. Search results can also be pre-approved, such as “qualified” parts based on company criteria to drive preferred part into product designs.Once you have identified the correct part, it can be placed directly into your schematic design from the database search results. OrCAD CIS will automatically transfer all of the associated component properties, eliminating hand-typing of part properties.

Databases

OrCAD CIS works with any database that is compliant with Microsoft’s ODBC standard to directly access your company component data in corporate MRP, ERP, or PLM systems, or in a local, intermediate database dedicated to engineering component data. OrCAD CIS also allows for the creation and use of relational tables in the component parts database.These relational tables have a one-to-many relationship with the part information (primary) tables. The relational database may contain a vendor table with multiple vendor/manufacture part numbers for a single company part number in the electrical (e.g., resistor) table. With this structure, search and query for data across the primary and relational tables provides more intelligent, refined results.

New part introduction and tracking

As you create new parts during the design process, you can keep track of them through the OrCAD CIS part-approval system. New parts can easily be created by duplicating and editing an existing record in the component database, and automatic alerts be issued when a temporary part is assigned a corporate part number and promoted to preferred or approved status.

Verification

Ensuring component data integrity throughout the design process is critical to project success. It is a key capability of OrCAD CIS through the validation of component properties against a corporate database. A simple property change, such as the value of a resistor, can result in a mismatch between the schematic part and the part information in the database.

The impact of this mismatch could be significant if the wrong part is ordered since the part number and corresponding value will not match. OrCAD CIS displays colored indicators to identify parts with unresolved problems as well as which properties are out of sync with the database. If the value of placed part’s property is green,then it matches the value of the property for the database part. If the value of placed part’s property is red, then the value does not match that of the database part.

Component Management Solutions and Flows

Variants

With the design variants capability, included as part of OrCAD CIS, you can manage unlimited board assembly variations without having to maintain duplicate schematics or manually edit individual BOMs. This capability reduces the number of files by maintaining all design-assembly variations within a single design and outputs. On the schematic canvas, substituted and/or unplaced components within each assembly are displayed through graphical indicators for easy reference.

Advanced documentation

You can take BOM and report generation to the next level with Crystal Reports included in OrCAD CIS. Not limited to just those properties that reside in the schematic, OrCAD CIS and Crystal Reports draw from the extensive information that resides in your component part databases. This allows you to create customized report templates with more advanced features than a standard CIS BOM.

Open Architecture Platform

Enabling an extensible and customizable design environment, the OrCAD open architecture platform incorporates a highly integrated Tcl/HTML5 programming infrastructure that allows the creation or enhancement of features, functionality, design capabilities, and flows. The Tcl programming interface provides programming access to the user interface.

Product Details

Product Details

Success Cases

Success Cases